Hydrogen at Pressure: Designing Safety and Performance into the Future of Energy

“The world is advancing rapidly in its pursuit of cleaner energy — from the rise of renewables like solar and wind, to the growth of hydrogen technologies. This global transition brings both opportunity and challenge, particularly in delivering safe, high-performance infrastructure that can balance supply and demand. At HEROSE UK, we’re proud to be part of this exciting journey toward a safer, more sustainable energy future.” – Barry Stewart

As industries accelerate toward cleaner energy, hydrogen is emerging as one of the most promising fuels of the future. But working with hydrogen at high pressures presents unique engineering and safety challenges that demand experience, innovation and absolute precision.

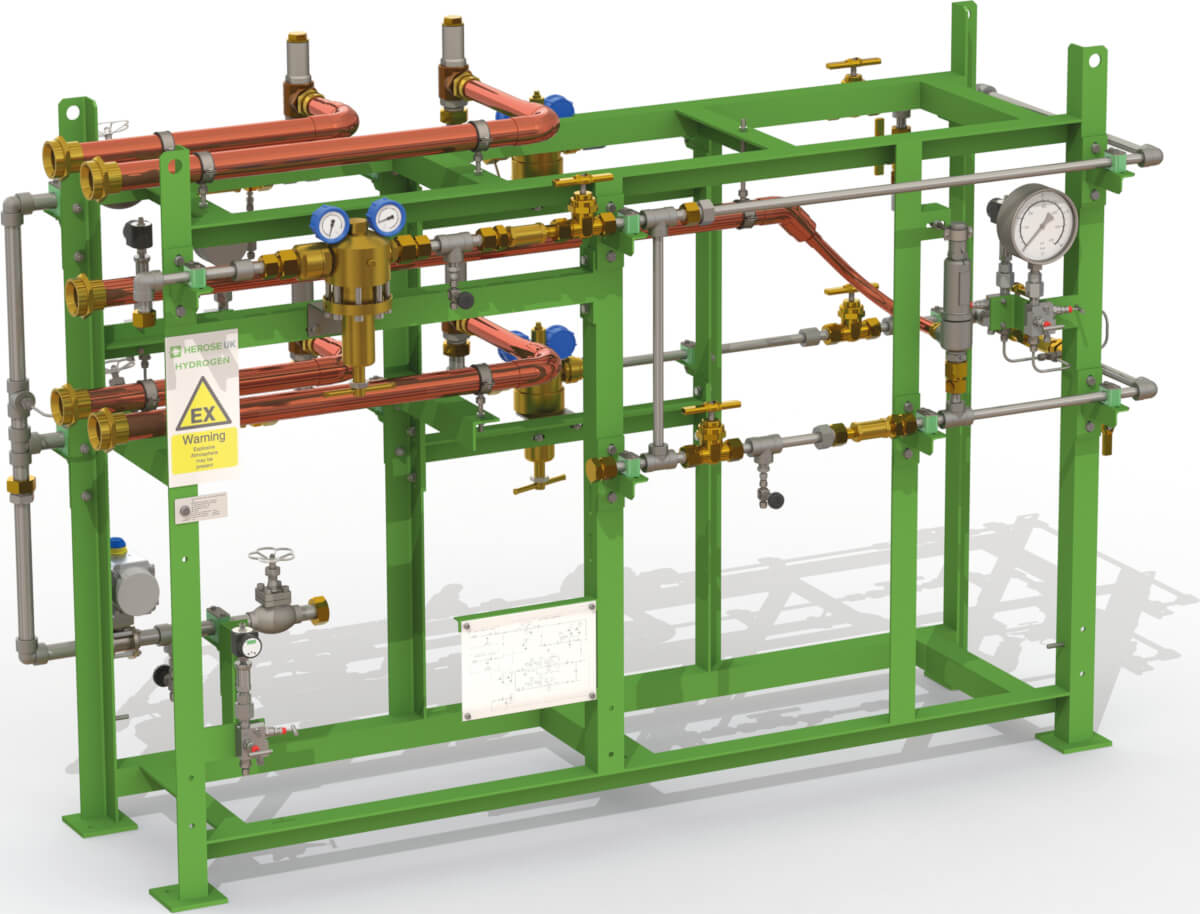

At HEROSE UK, we’ve been advancing valve and modular technology for industrial gas applications for over two decades. Our latest hydrogen modules demonstrate how safety-led design can simplify installation, enhance performance, and prepare facilities for the next generation of clean energy delivery.

The pressure challenge

Hydrogen requires uncompromising safety at every stage of handling and distribution. When stored and transported as a compressed gas, pressures can reach up to 500 barg, putting extreme demands on system integrity.

Facilities using trailer-based delivery or buffer storage systems face increasing complexity. Variations in trailer pressures, site layouts, and end-use requirements mean every installation has to be precisely configured to ensure consistent flow, accurate regulation and fail-safe operation.

The challenge is not only engineering one system that performs reliably under such demanding conditions — but standardising that safety and performance across multiple sites and applications.

From complexity to confidence

HEROSE UK’s Bulk High Pressure Gaseous Hydrogen (H2) Modules are designed to make that standardisation a reality. Each module is fully engineered, assembled and tested prior to delivery, giving gas companies and operators a pre-validated solution that meets global safety and performance standards.

Available configurations include trailer fill, regulator and vent-stack modules — all designed to work together as a cohesive system. Each module is rated for up to 300 barg settled trailer pressure at +15 °C, with design flexibility to support future 350–500 barg delivery pressures.

The result? A modular system that adapts easily to evolving site requirements — while keeping operators, equipment and end users safe.

Safety and performance built in

From concept to commissioning, safety is engineered into every detail:

- Dual-stage pressure control (spring or dome-loaded regulators) ensures stable and accurate outlet pressures.

- Integrated Emergency Shut-Off Valves (ESOVs) provide rapid isolation as standard.

- Vent stacks with individual PSV outlets ensure vertical venting and protection from rain or snow ingress.

- Optional nitrogen purge systems support safe commissioning and maintenance.

- Flat-face fittings simplify future service and minimise downtime.

- Options for instruments and additional high pressure ESOVs improving operational safety, based on site risk analysis.

- Options for electrical control panel, with integration of supplier telemetry (panel mounted in safe area).

Every feature reflects HEROSE UK’s core design philosophy: to combine innovation with real-world practicality — delivering solutions that make operations safer and more efficient.

HEROSE UK’s Hydrogen Module Range:

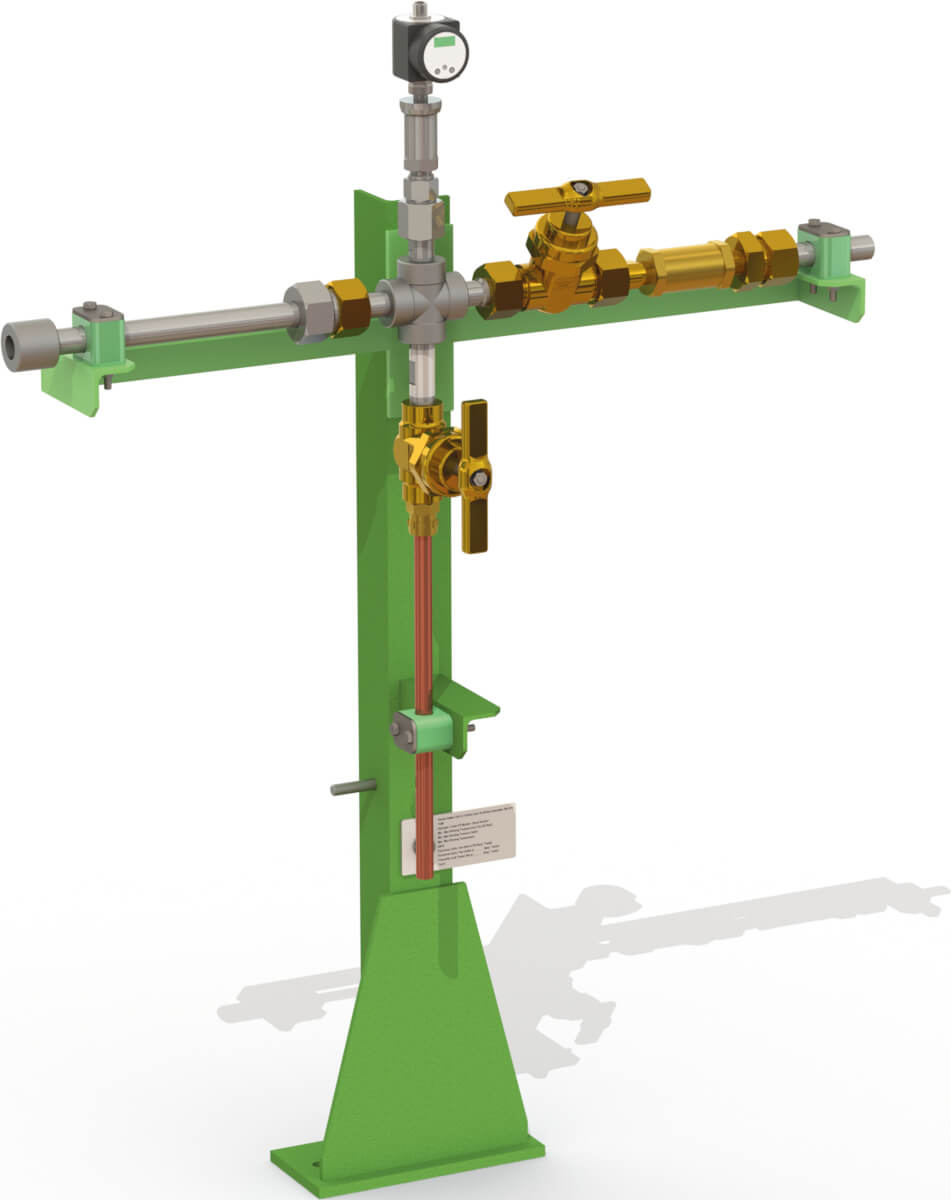

H2 Trailer Fill Module

- Connects safely between trailer and regulator module

- Provides flexibility on trailer inlet connections and the number of trailer ports

- Height: 1 m × Width 0.8 m × Depth 0.3 m

- Weight: 25 kg

H2 Vent Stack Module

- Module provided with pre-piped vent stack and pipework (copper or stainless-steel options) for efficient installation

- Vent stack provides individual vents; vertical venting of hydrogen PSVs for safety & rain/snow ingress protection

- Height: 6 m × Width 1.3 m × Depth 0.65 m

- Weight: 395 kg

All modules are available with optional high-pressure ESOVs, nitrogen purge systems for commissioning and maintenance, prefabricated interconnecting spools between trailer connection(s), and digital documentation via HEROSE UK’s portal — providing complete certification control and traceability.

Efficiency by design

Beyond safety, the H2 modules deliver measurable operational benefits:

- Installation times reduced by over 50%, saving real time and cost.

- Standardised components provide a consistent, standardised solution for all installations — simplifying site setup and reducing supplier complexity.

- One part number gives customers a fully assembled, tested, and certified module ready for immediate use.

- A digital portal provides complete documentation and certification control — ensuring traceability and compliance.

This isn’t just smart engineering — by standardising the complex, HEROSE UK helps operators focus on performance, not paperwork.

Engineering innovation for a hydrogen future

Hydrogen technology is evolving fast. With demand growing across mobility, power generation, and industrial applications, the ability to handle higher pressures safely and efficiently will be critical.

HEROSE UK’s H2 modules are already proven in operation, designed and built to meet today’s standards — and tomorrow’s ambitions. They reflect our commitment to innovation beyond expectation: helping industry partners open the door to unlimited possibilities in hydrogen and industrial gas applications.

Watch the video below to learn more about our Bulk High-Pressure Gaseous Hydrogen Modules: