Low Temperature Protection – Is your facility safe?

“One of the most significant challenges faced by the industrial gases industry today is ensuring the safety and compliance of cryogenic systems.”

– Keith Stewart

Without the correct design and engineering input, cryogenic systems can become overdrawn and dangerous. The threat is real – every year, failures in these systems cause injuries and even fatalities. Carbon steel brittle fracture is an example of a key safety risk that can occur when cryogenic systems are overdrawn. Carbon steel becomes brittle under exposure to cold temperatures and stress/impact. This can result in the release of large amounts of stored energy in an uncontrolled way, and fragmenting carbon steel can cause major damage to pipe and/or buffer vessels, and serious injury or death to personnel.

It is therefore essential that cryogenic installations are properly designed, with careful consideration of end user specifications, and in strict compliance with the global standards for low temperature protection, CGA P-56 & EIGA 133. These standards protect staff, customer sites and the industry.

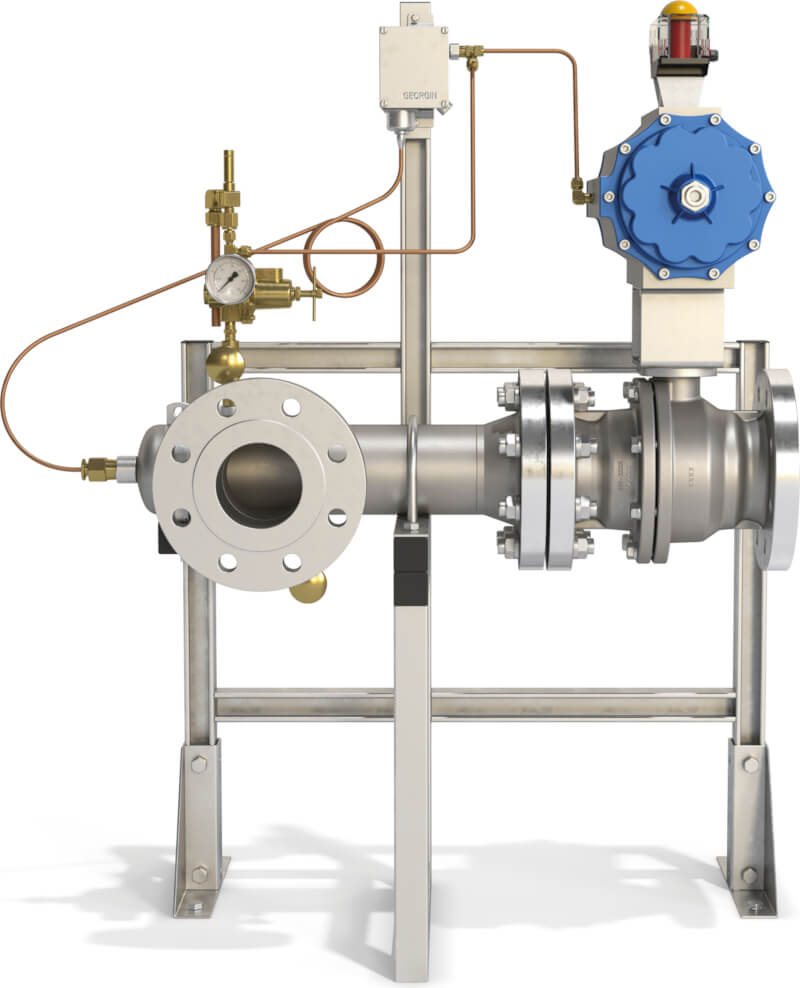

HEROSE UK has developed several modular ranges of Low Temperature Protection Systems (LTPS), which protect carbon steel pipework and carbon steel buffer vessels on both the cryogenic supply system, and the customer’s process equipment. HEROSE UK’s LTPS are available for use on mini-bulk and bulk cryogenic liquid storage, vaporisation and distribution systems.

The LTPS is designed to be installed on the vaporiser outlet on a gaseous withdrawal application, to prevent cold gas or cryogenic liquid from entering the distribution pipeline or reaching the user’s process, thus guarding against the dangers of carbon steel brittle fracture.

Furnace Atmospheres

HEROSE UK can also provide support for furnace atmosphere applications, including Module selection and alarm panel options for these systems.

HEROSE UK’s LTPS ranges:

Stainless Steel LTPS Module Ranges

Designed for higher flow bulk applications, where low temperature protection is required.

- Modules are fail-closed design.

- Sizes from DN65 to DN100 PN40 (2-1/2" to 4" CL300) flanged options are matched to suit customer flow ranges.

- Both auto-reset and manual reset designs are offered to allow selection based on vaporiser type or operating preference.

- Different trip point settings can be provided, normally -12°C / +10.4°F for carbon dioxide, and -18°C / -0.4°F for air gases, including oxygen.

- Modules are stainless steel construction, 40 Barg / 580 Psig design pressure (23.5 Barg / 340 Psig oxygen design pressure).

- Module designs are matched to CGA and EIGA selection matrix outputs.

2oo3 Voting LTPS Module Ranges

Designed for higher flow bulk applications, where low temperature protection is required along with supply security preventing unnecessary trips. 2oo3 voting logic included.

- Modules are fail-closed design.

- Size DN80 PN40 (3" CL300) flanged options are matched to suit customer flow ranges.

- Manual reset design, with -15°C / +5°F alarm, and -18°C / -0.4°F trip.

- Modules are stainless steel construction, with 40 Barg / 580 Psig design pressure (23.5 Barg / 340 Psig oxygen design pressure).

- Remote signal connections available.

- Optional UPS panel providing ~30 minutes emergency operation after site power failure.

- Module designs are matched to CGA and EIGA selection matrix outputs.

Watch episode 1 of our new animated series. Join our engineer on his visit to an industrial gas site to advise on Low Temperature Protection and explain how HEROSE UK’s product solutions ensure compliance, safety and performance for global gas companies.

Installed on both mini-bulk and bulk cryogenic installations, where low temperature protection is required.

Installed on both mini-bulk and bulk cryogenic installations, where low temperature protection is required. Designed for higher flow bulk applications, where low temperature protection is required.

Designed for higher flow bulk applications, where low temperature protection is required. Designed for higher flow bulk applications, where low temperature protection is required along with supply security preventing unnecessary trips. 2oo3 voting logic included.

Designed for higher flow bulk applications, where low temperature protection is required along with supply security preventing unnecessary trips. 2oo3 voting logic included.