Addressing the danger of oxygen depletion in the industrial gas industry

When working with industrial gases, safety is paramount. One of the major safety concerns faced by the industrial gas industry today, is that of oxygen depletion of working environments due to liquid nitrogen leaks. The consequences are serious and life threatening – oxygen depletion is responsible for a number of injuries and deaths every year. Unregulated discharges of liquid carbon dioxide, another commonly used cryogenic gas, also pose a danger to the atmosphere of working environments.

The dangers of Oxygen Deficient Atmospheres and their specific engineering requirements are set out in the industry standards CGA P-76 & SA-41 with EIGA 174 & 044. These standards highlight the need for proper education, training, and technology to safeguard personnel and ensure compliant working environments.

Our commitment to safety and quality

At HEROSE UK, we are committed to addressing the specific safety concerns of the industry and for the last 15 years, our design and engineering teams have been dedicated to developing modular solutions specifically designed to tackle critical safety issues, such as oxygen depletion.

Our product solutions to ensure safety in liquid cryogenic gas storage and supply, include the following:

Cryogenic Solutions

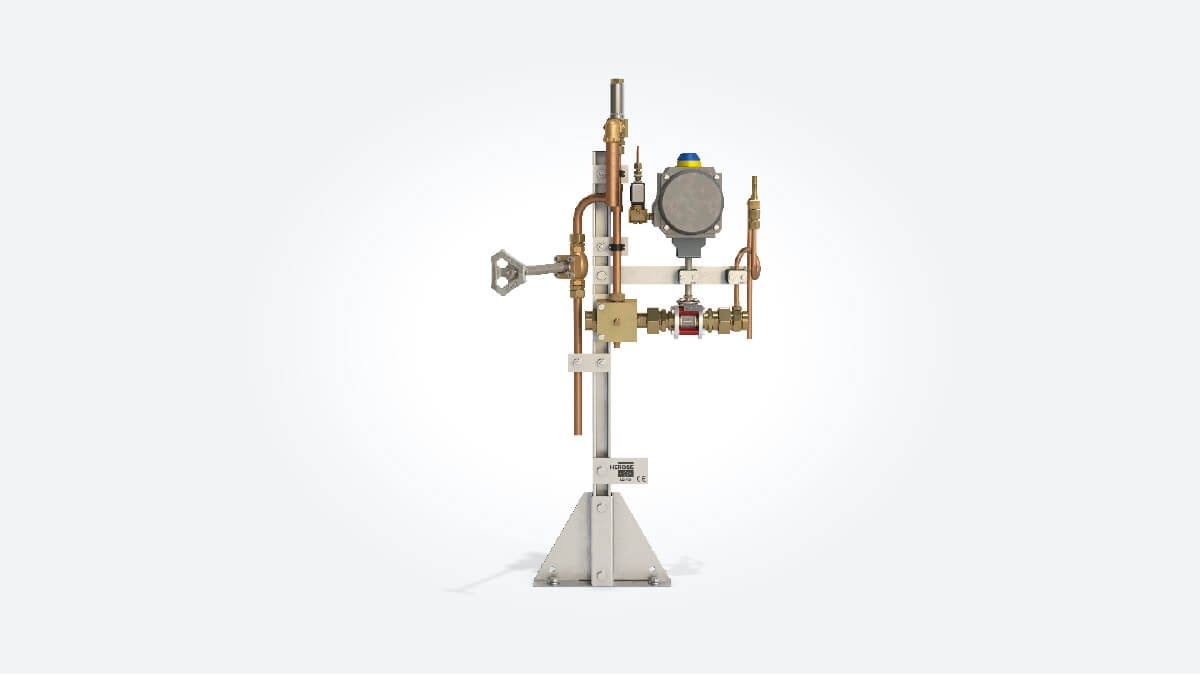

These safety-first modules include a range of Emergency Shut-Off Valves (ESOVs; fail-closed type) for installation on mini-bulk and bulk cryogenic liquid nitrogen supply lines. These ESOV modules are designed to isolate the cryogenic supply line when triggered. Activation occurs via a signal from the internal gas detection system, in response to low pressure ‘top gas’ from the cryogenic liquid supply vessel. This system prevents both gradual and catastrophic leaks by shutting off the cryogenic liquid supply at its source, so that only the contents of the damaged liquid nitrogen pipe will leak into the building, minimising danger and damage.

Solutions include options for continuous supply and batch/shift operations to provide the necessary flexibility and ensure safe and compliant working environments.

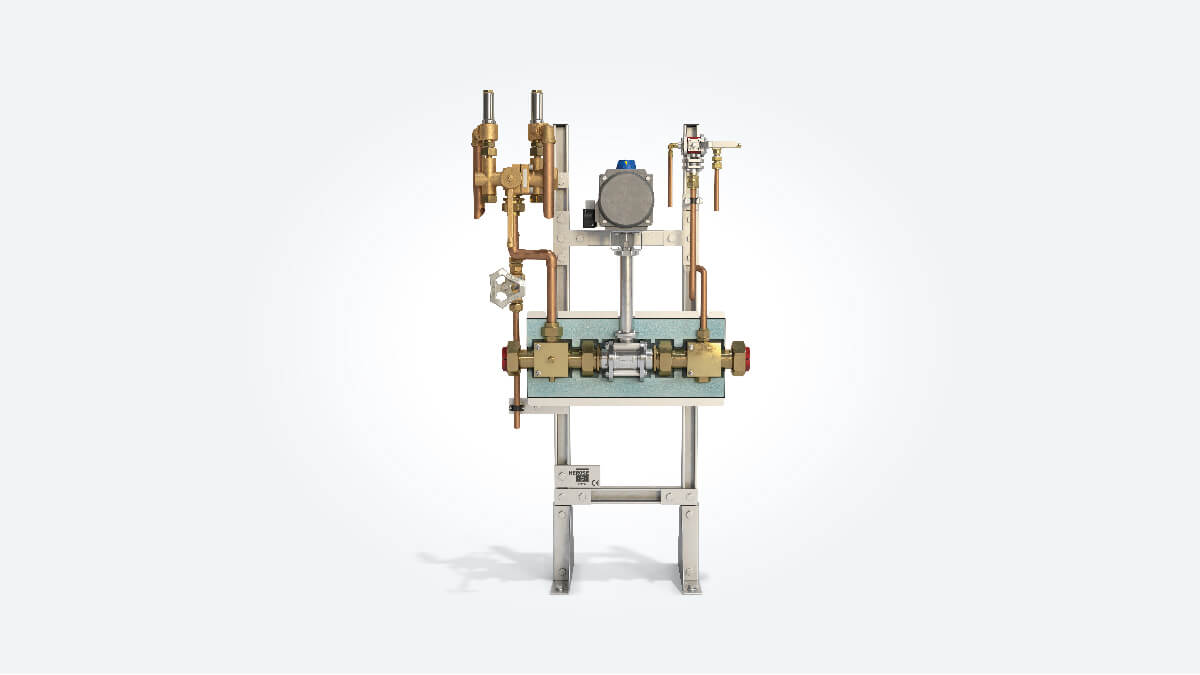

Low Pressure Liquid Control Panel Module

This range of panel assemblies is used with ambient pressure raising vaporisers on bulk cryogenic liquid nitrogen storage vessels and can be easily adjusted to suit site operating conditions. The panel provides accurate cryogenic liquid supply pressure to the process through electronic control of both cryogenic vessel pressure raising and top gas venting to the atmosphere through a silencer—this helps to deliver consistent product freeze quality. Additional mechanical backup systems are also provided in case of power failure/emergency to allow production to continue without any interruption.

Tanker Inlet Filter Module

These filter assemblies are designed to be installed on the tanker filling line and include a hose purge before cryogenic liquid delivery. The module strainer (100-micron sinter bronze as standard) helps protect the vessel from contamination. A product-specific tanker hose coupling is included, preventing cross-filling of the wrong liquid product. Options are available for both CGA and EIGA coupling types. Additional module options include a cryogenic non-return valve to prevent back-feed into the delivery tanker, as well as thermal relief protection. Remote fill point designs are also available, providing fill line isolation, purge, and thermal relief protection.

By prioritising safety and innovation, we’re addressing the danger of oxygen depletion and enhancing the safety of working environments in the industrial gas industry, setting new standards for operational excellence.

Ready to enhance safety and efficiency? Contact HEROSE UK today to learn more about our innovative solutions and how we can tailor them to meet your specific needs, whilst safeguarding your workforce and elevating your operations.

Watch Episode 2 of our new animated series! Join our engineer as he explores a cryogenic installation at a food freezing factory, highlighting the dangers of oxygen deficient atmospheres. Discover how HEROSE UK’s Emergency Shut-off Valves ensure compliance, safety, and performance for global gas companies.