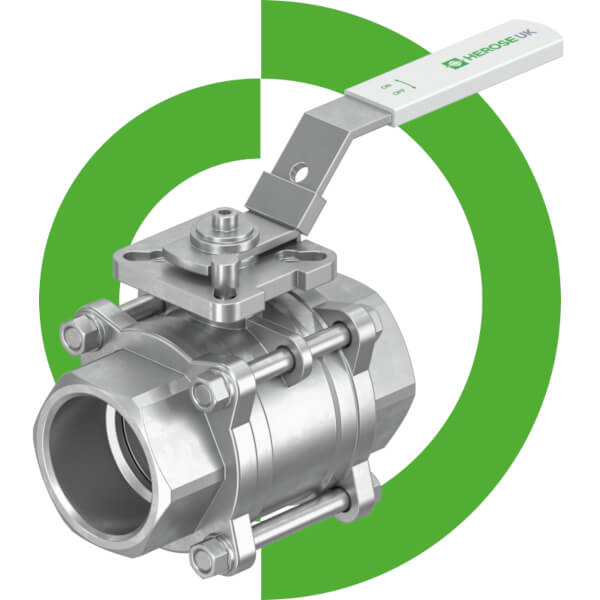

HEROSE UK’s range of Ball Valves have been specifically designed to meet demanding operational requirements, including that of high purity applications. The product ranges meet ASME, DIN, and JIS standards, for the valve package that includes 1pc, 2pc, 3pc body, multiple-port & V-ported valve designs with standard pressure ratings 1000PSI, 2000PSI, and 3000PSI, to high pressure 6,000 and 10,000PSI. Products for NACE MR-01-75, Atex 2014/34/EU, TRD100, low emission ISO15848-1, and fire-safe API 607 are available as standard.

Materials: Fully controlled and available with EN10204 3.1 certificates.

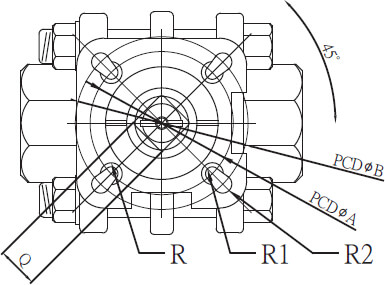

Direct Mounting Pad: Improves control accuracy, and facilitates maintenance by providing a direct and robust attachment point for mounting actuators onto the valve body.

Application: Our valves are suitable for Automotive, Gas & Oil, Chemical, Water & Wastewater, Mining, Minerals & Metals, Marine, Pulp & Paper, Food & beverage, and Pharmaceutical industries.

| Size | 1/4”- 4” / DN08-100 |

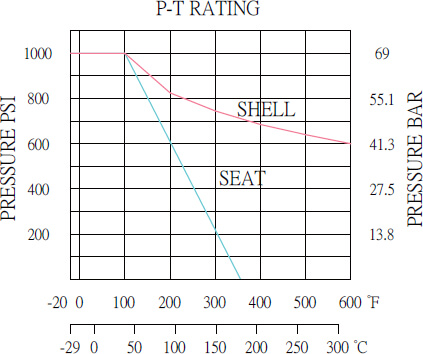

| Pressure Rating | 1000 PSI / PN63 |

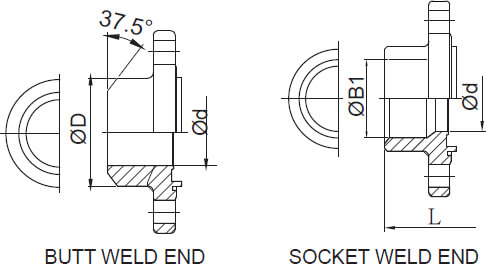

| End Connections | Threaded / BW / SW |

| Mounting Pad | ISO 5211 Direct |

| Material | CF8M / WCB 1.4408 / 1.0619 |

Every detail of our V302 screwed and weld connection ball valves is engineered for strength, safety, and long-term performance. From body and stem design to seat materials and inspection standards, each component is specified to deliver reliability in demanding industrial environments.

Body

Seat/Seal

Stem Packing

Ball Seat

Connections

Marking

Stem

Seat

Thrust Washer

Length

Handle Nut/Bolt

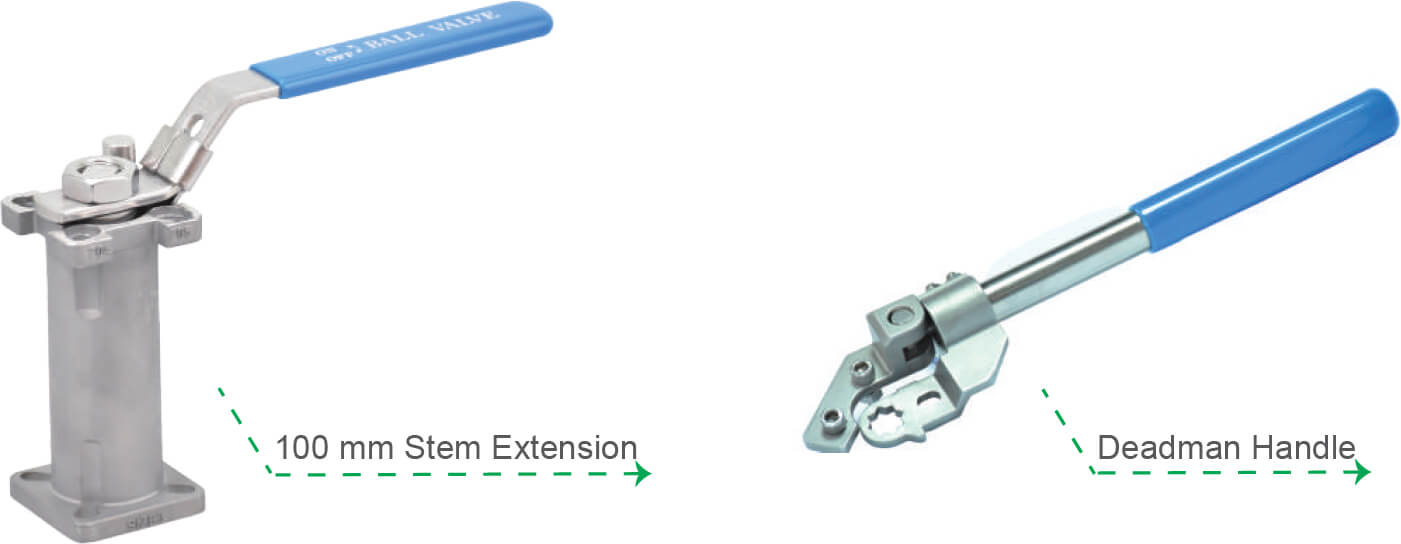

Extension & Handles

Lock Washer

Positioning

Platform

Inspection

Talk to Our Manual Threaded 3-piece Ball Valves Expert

Whether you’re specifying valves for a new process line or upgrading existing equipment, Wayne is here to help. With years of experience in industrial and hygienic valve solutions, he can guide you to the right product for your application. Get in touch today for expert advice, technical support, and a competitive quote.

T: +44 (0) 7901 127 265

E: wayne.lyons@herose.co.uk

T: +44 (0) 7901 127 265

E: wayne.lyons@herose.co.uk

Wayne Lyons

Industrial Valve Sales Manager

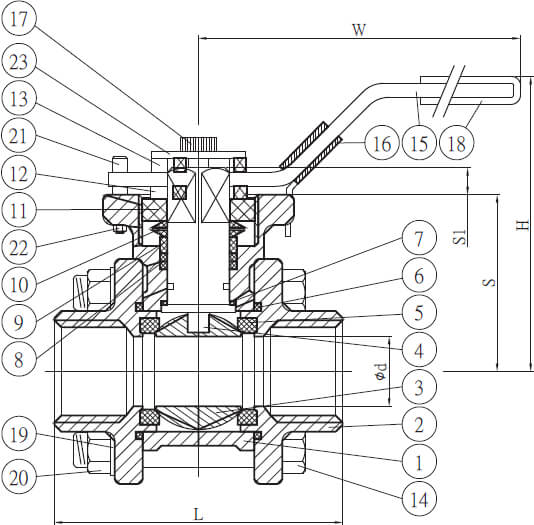

| SIZE | Ød | End-to-End ± 2 | H±5 | W +0 W-10 | S | S1 | ØB | ØD | ØB1 | ISO 5211 | R | Torque (Nm) | ||||||

| L | LB | B16.11 | EN 12760 | Ø Pcd A | Ø Pcd B | R1 | R2 | Q | ||||||||||

| 1/4" | 11 | 55 | 55 | 68 | 117 | 37 | 8.0 | 9.22 | 13.7 | 14.2 | 14.2 | F03/Ø36 | F04/Ø42 | R3.0 | R3.0 | 9.0 | 4.3 | 4.0 |

| 3/8" | 12.7 | 60 | 55 | 68 | 117 | 37 | 8.0 | 12.48 | 18 | 17.6 | 17.6 | F03/Ø36 | F04/Ø42 | R3.0 | R3.0 | 9.0 | 4.3 | 4.0 |

| 1/2" | 15 | 75 | 60 | 70 | 117 | 38 | 8.5 | 15.76 | 22 | 21.8 | 21.8 | F03/Ø36 | F04/Ø42 | R3.0 | R3.0 | 9.0 | 4.3 | 5.4 |

| 3/4" | 20 | 80 | 75 | 69 | 127 | 41.7 | 9.0 | 20.96 | 28 | 27.2 | 27.2 | F03/Ø36 | F04/Ø42 | R3.0 | R3.0 | 11 | 4.3 | 7.4 |

| 1" | 25 | 90 | 80 | 78 | 170 | 44.4 | 9.0 | 26.64 | 34 | 33.9 | 33.9 | F04/Ø42 | F05/Ø50 | R3.0 | R3.5 | 11 | 5.5 | 10.4 |

| 1-1/4" | 31.8 | 110 | 95 | 89 | 154 | 54 | 10.5 | 35.08 | 41 | 42.7 | 42.7 | F04/Ø42 | F05/Ø50 | R3.0 | R3.5 | 14 | 5.5 | 13.5 |

| 1-1/2" | 38 | 120 | 105 | 100 | 182 | 59.5 | 10.5 | 40.94 | 49 | 48.8 | 48.8 | F05/Ø50 | F07/Ø70 | R3.5 | R4.5 | 14 | 5.5 | 18 |

| 2" | 50 | 140 | 120 | 107 | 182 | 67 | 10.5 | 52.48 | 62 | 61.5 | 61.5 | F05/Ø50 | F07/Ø70 | R3.5 | R4.5 | 14 | 5.5 | 25 |

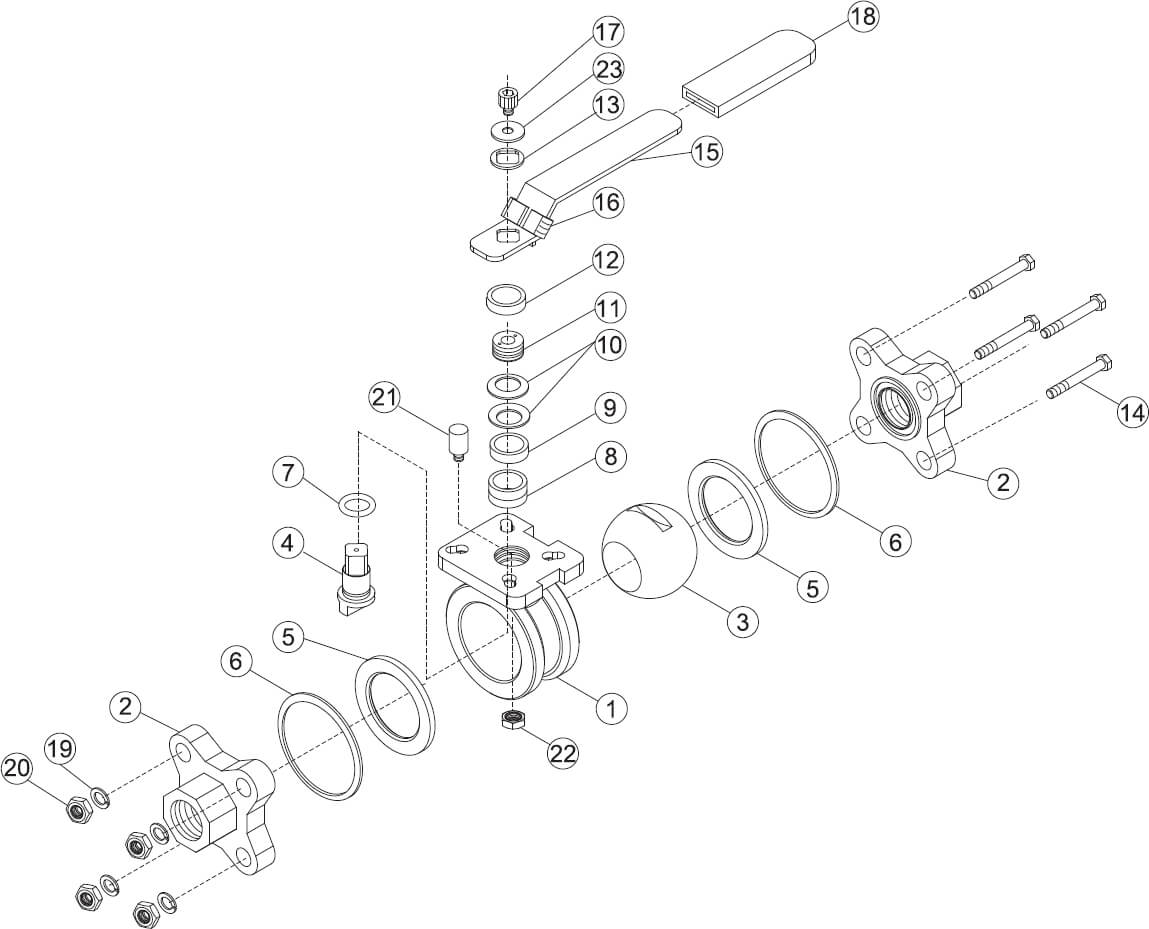

| Item | Part | Qty. | Materials |

| 316 | |||

| 1 | Body | 1 | CF8M / 1.4408 |

| 2 | End Cap | 2 | CF8M / 1.4408 |

| 3 | Ball | 1 | CF8M / 1.4408 |

| 4 | Stem | 1 | 316 |

| 5 | Seat | 2 | RPTFE |

| 6 | Body Seal | 2 | RPTFE |

| 7 | Thrust Washer | 1 | PTFE |

| 8 | Stem Packing | 2 | PTFE |

| 9 | Gland Ring | 1 | 304 |

| 10 | Disc Spring | 2 | 301 |

| 11 | Insert | 1 | 301 |

| 12 | Spacer | 1 | RPTFE |

| 13 | Spacer | 1 | 304 |

| 14 | Body Bolt | 4 | 304 |

| 15 | Handle | 1 | 304 |

| 16 | Lock Device | 1 | 304 |

| 17 | Bolt | 1 | 304 |

| 18 | Handle Sleeve | 1 | Plastic |

| 19 | Spring Washer | 4 | 304 |

| 20 | Hex Nut | 4 | 304 |

| 21 | Stop Pin | 1 | 304 |

| 22 | Nut for Part 22 | 1 | 304 |

| 23 | Washer | 1 | 304 |