HEROSE UK’s V36MH is a 3-piece hygienic ball valve designed for food, biological, pharmaceutical, and similar industries. With an ISO direct mounting pad, it offers easy installation and integration with other equipment. Certified to meet EC 1935 and 3-A Sanitary Standards, this valve ensures compliance with industry regulations.

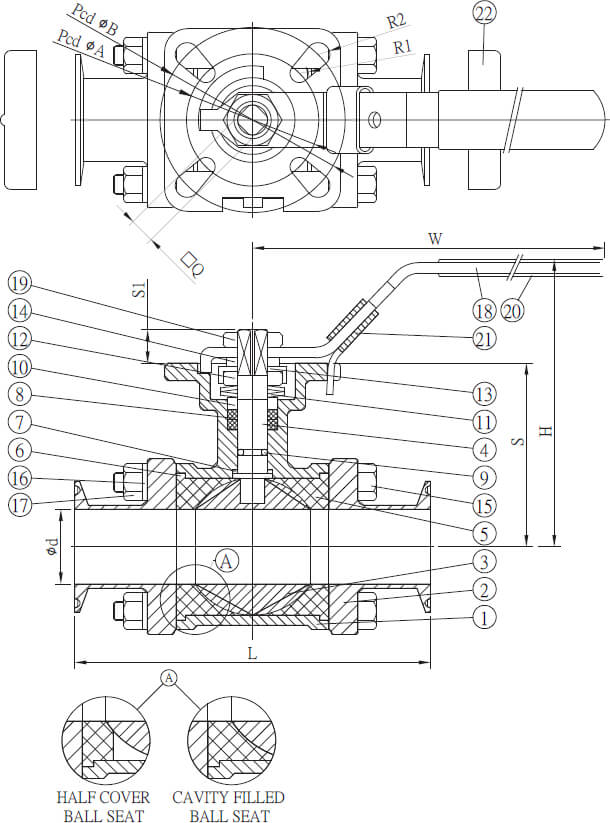

Featuring a blow-out proof stem and a lock device, the V36MH prioritizes safety and reliable operation. The cavity filled ball seat eliminates media retention, preventing spoilage and facilitating easy cleaning of the valve port.

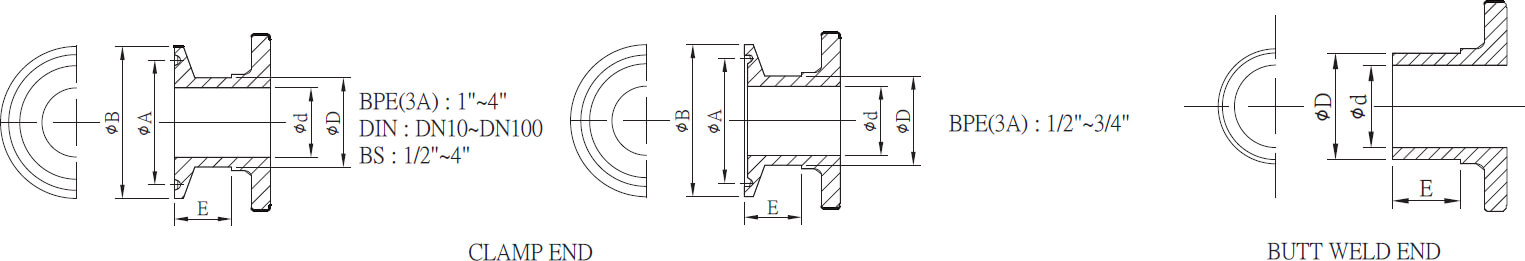

With options for butt weld and clamp end connections, the V36MH provides flexibility to suit specific installation requirements. Its inside port has a smooth surface finish (Ra < 0.4um) for efficient flow.

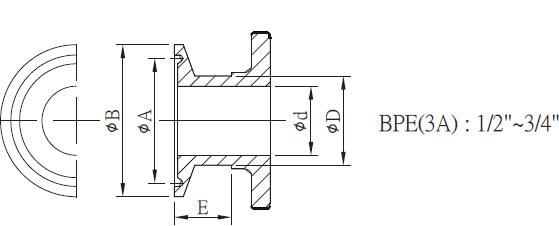

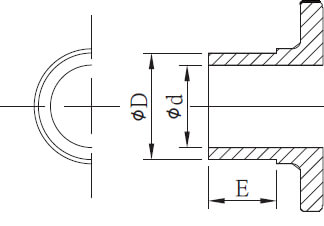

Complying with ASME Bl6.34/EN 12516 design standards, EN12516-2 wall thickness standards, ASME BPE (3A) clamp end, ASME BPE (3A) butt weld end, DIN 32676 H4 inside surface finish, and API598/ EN 12266-1 inspection and testing standards, the V36MH ensures quality, performance, and reliability.

Choose the V36MH for a high-quality hygienic ball valve that meets the stringent demands of food, biological, pharmaceutical, and related industries.

It offers functionality, ease of maintenance, and compatibility with various actuators.

Trust HEROSE UK for reliable valve solutions.

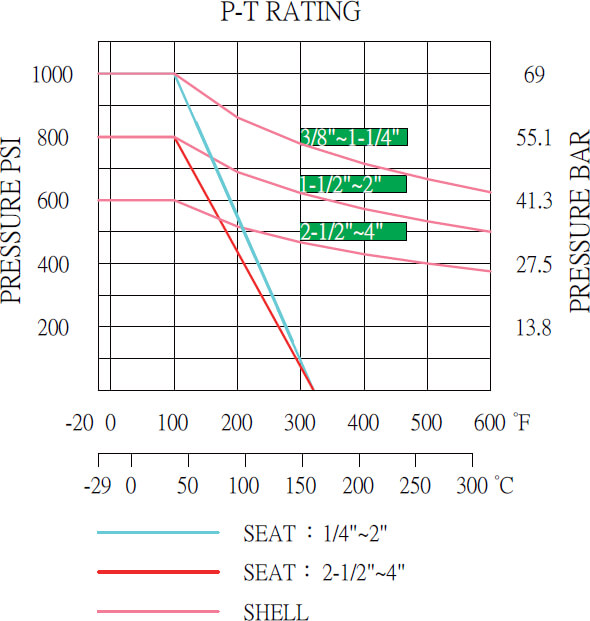

| Size | 1/2" to 4" / DN15-100 |

| Pressure Rating | 1000 PSI / PN63 |

| End Connections | Clamp / OD Welding |

| Mounting Pad | ISO 5211 Direct |

| Material | CF8M / 1.4408 |

Our hygienic ball valves are engineered with precision features that enhance performance, safety, and service life in demanding sanitary applications. From a swing-out, investment-cast body for easy maintenance, to FDA-certified sealing materials and mirror-polished flow paths, every component is designed for hygiene, reliability, and efficiency. Explore the key details and benefits that set our valves apart in food, beverage, pharmaceutical, and other clean-process environments.

Body

Stem Packing

Ball Seat

Seat/Seal

Marking

Connections

Stem

Seat

Thrust Washer

O-Ring

Handle Nut/Bolt

Positioning

Handle

Platform

Inspection

Talk to Our Hygienic Ball Valve Expert

Whether you’re specifying valves for a new process line or upgrading existing equipment, Wayne is here to help. With years of experience in industrial and hygienic valve solutions, he can guide you to the right product for your application. Get in touch today for expert advice, technical support, and a competitive quote.

T: +44 (0) 7901 127 265

E: wayne.lyons@herose.co.uk

T: +44 (0) 7901 127 265

E: wayne.lyons@herose.co.uk

Wayne Lyons

Industrial Valve Sales Manager

| ØD (mm) | Max Pressure (bar) |

|---|---|

| 6.35 ~ 42.4 | 25 |

| 48.3 ~ 76.2 | 16 |

| 85 ~ 219.1 | 10 |

| SIZE | BPE(3A) | DIN | BS | ISO 5211 | L±2 | H | W | E | S | S1±1 | Torque (Nm) | ||||||||||||||||

| NPS | DN | Ød | ØD | ØA | ØB | Ød | ØD | ØA | ØB | Ød | ØD | ØA | ØB | Pcd ØA | Pcd ØB | R1 | R2 | Q | |||||||||

| 3/8 | 10 | - | - | - | - | 10 | 13 | 27.5 | 34 | - | - | - | - | F03 | Ø36 | F04 | Ø42 | 3 | 3 | 9 | 79 | 53 | 95 | 21.5 | 33 | 10 | 2.5 |

| 1/2 | 15 | 9.4 | 12.7 | 20.2 | 25 | 16 | 19 | 27.5 | 34 | 9.5 | 12.7 | 20.3 | 25.4 | F03 | Ø36 | F04 | Ø42 | 3 | 3 | 9 | 89 | 57 | 95 | 21.5 | 36.5 | 10 | 3.5 |

| 3/4 | 20 | 15.75 | 19.05 | 20.2 | 25 | 20 | 23 | 27.5 | 34 | 15.85 | 19.05 | 20.3 | 25.4 | F03 | Ø36 | F04 | Ø42 | 3 | 3 | 9 | 101 | 64 | 95 | 25 | 44 | 10 | 5 |

| 1 | 25 | 22.1 | 25.4 | 43.5 | 50.5 | 26 | 29 | 43.5 | 50.5 | 22.2 | 25.4 | 43.5 | 50.5 | F04 | Ø42 | F05 | Ø50 | 3 | 3.5 | 11 | 114 | 75 | 120 | 28.7 | 52 | 12 | 7.5 |

| 1-1/4 | 32 | - | - | - | - | 32 | 35 | 43.5 | 50.5 | - | - | - | - | F04 | Ø42 | F05 | Ø50 | 3 | 3.5 | 11 | 127 | 81 | 120 | 28 | 57.5 | 12 | 12 |

| 1-1/2 | 40 | 34.8 | 38.1 | 43.5 | 50.5 | 38 | 41 | 43.5 | 50.5 | 34.9 | 38.1 | 43.5 | 50.5 | F05 | Ø50 | F07 | Ø70 | 3.5 | 4.5 | 14 | 140 | 100 | 150 | 29.7 | 69.3 | 16 | 15 |

| 2 | 50 | 47.5 | 50.8 | 56.5 | 64 | 50 | 53 | 56.5 | 64 | 47.6 | 50.8 | 56.5 | 64 | F05 | Ø50 | F07 | Ø70 | 3.5 | 4.5 | 14 | 156 | 109 | 150 | 31 | 78.5 | 16 | 28 |

| 2-1/2 | 65 | 60.2 | 63.5 | 70.5 | 77.5 | 66 | 70 | 83.5 | 91 | 60.3 | 63.5 | 70.5 | 77.5 | F07 | Ø70 | F10 | Ø102 | 4.5 | 5.5 | 17 | 197 | 135 | 215 | 37∅.5B | 101 | 19 | 40 |

| 3 | 80 | 72.9 | 76.2 | 83.5 | 91 | 81 | 85 | 97 | 106 | 73 | 76.2 | 83.5 | 91 | F07 | Ø70 | F10 | Ø102 | 4.5 | 5.5 | 17 | 229 | 145 | 215 | 46 | 111 | 19 | 65 |

| 4 | 100 | 97.38 | 101.6 | 110 | 119 | 100 | 104 | 110 | 119 | 97.6 | 101.6 | 110 | 119 | F07 | Ø70 | F10 | Ø102 | 4.5 | 5.5 | 17 | 241 | 160 | 300 | 37.5 | 126.5 | 19 | 90 |

CLAMP END

CLAMP END

BUTT WELD END

| No. | Part | Qty. | Material | |

| 316 | 304 | |||

| 1 | Body | 1 | CF8M | CF8 |

| 2 | End Cap | 2 | CF8M | CF8 |

| 3 | Ball | 1 | CF8M | CF8 |

| 4 | Stem | 1 | 316 | 304 |

| 5 | Seat | 2 | PTFE | |

| 6 | Body Seal | 2 | PTFE | |

| 7 | Thrust Washer | 1 | PTFE | |

| 8 | Stem Seal | 2 | PTFE | |

| 9 | O-Ring | 1 | Silicone | |

| 10 | Gland Ring | 1 | 304 | |

| 11 | Disc Spring | 2 | 301 | |

| 12 | Stem Nut | 1 | 304 | |

| 13 | Lock Washer | 1 | 304 | |

| 14 | Spacer | 1 | 304 | |

| 15 | Body Bolt | 4-6 | 304 | |

| 16 | Spring | 4-12 | 304 | |

| 17 | Nut | 4-12 | 304 | |

| 18 | Handle | 1 | 304 | |

| 19 | Handle Nut | 1 | 304 | |

| 20 | Handle Sleeve | 1 | Plastic | |

| 21 | Lock Device | 1 | 304 | |

| 22 | End Cap Cover | 2 | Plastic | |